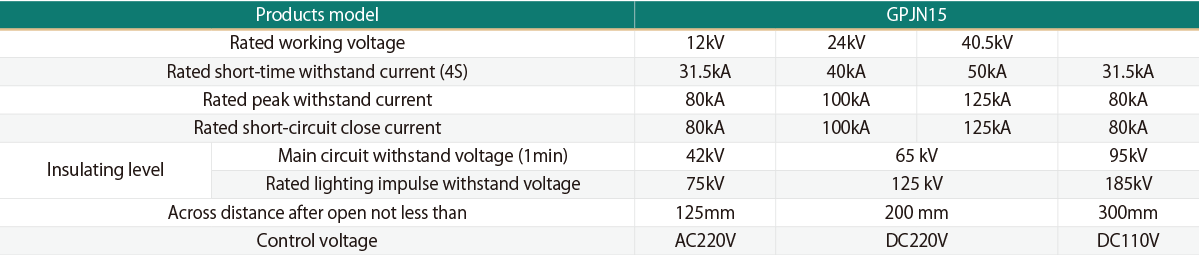

12/24/40.5kV Electric-drive Motorized Earthing Switch

Model

GPJN15-12 ( 24 ) /D31.5

Indoor high voltage motorized earthing switch

GPJN15-12/D40, 50

Indoor high voltage motorized earthing switch

GPJN15-40.5/D31.5

Indoor high voltage motorized earthing switch

General

GPJN15-12(24)/D31.5, GPJN15-12/D40, 50, GPJN15-40.5/D31.5 series indoor high voltage motorized earthing switch (short as: motorized earthing switch) is designed for the intelligent switchgear requirement of the electric system. It is suit for 3~40.5KV, 3 phase, AC 50 (60) Hz power system and kinds of high voltage switchgears. It is applicable for high voltage switchgear arrangement as the earthing protection when maintenance.

The products’ performance meet GB1985-2004 High Voltage AC Disconnector and Earthing Switch and the requirements of standard as well as IEC62271-102:2002.

Earthing switch structure is simple and compact, light weight, flexible operation, easy installation, dynamic thermal stability, and a reliable electric operation, keep the original interlocks in catching rabbits switchgear chain constant, has been a national patent.

Due to the earthing switch is electrically operated, The cabinet manually operated interlocks is still keep the same as original design, but there are some parts have been modified, be sure to use our company's matchable connection rod , otherwise it would be burned the motor of motorized earthing switch.

Since the earthing switch is electrically operated, and therefore the cabinet manually operated chain catching rabbits consistent with the original style, but there are some parts have been modified, be sure to use the matching connection rod of our company, otherwise it would be burned the motor of motorized earthing switch.

If the cabinet back door need interlocking with motorized earthing switch, also be sure to use the company's patented technology to produce backdoor interlock mechanism, and equipped travel switch.

When the back door is not closed, cutting off the operation power of motorized earthing switch to avoid motorized earthing switch of misuse and damage the motor.

When electric interlocking with the motorized earthing switch, be sure to use auxiliary contacts associated with electrical components to disconnect the operation power of the motorized earthing switch to achieve electrical interlock in order to ensure a reliable electrical interlock.

第二条

Condition of us

Ambient temperature: upper limit +45°C, lower limit -25°C

The altitude does not exceed 1000m (Standard); can up to 4500m for special ordering

Daily average value of relative humidity: ≤95%. Monthly average value of relative humidity: ≤90%

Earthquake intensity≤8 degree

Not available the following locations:

Installation site there is a serious grounding switch insulation and conductivity of gases, vapors, chemical precipitation, dust, dirt and smoke explosion aggressive substances; Installation place has frequent violent vibration.

第二条

Structure and working principle

1. Main structure

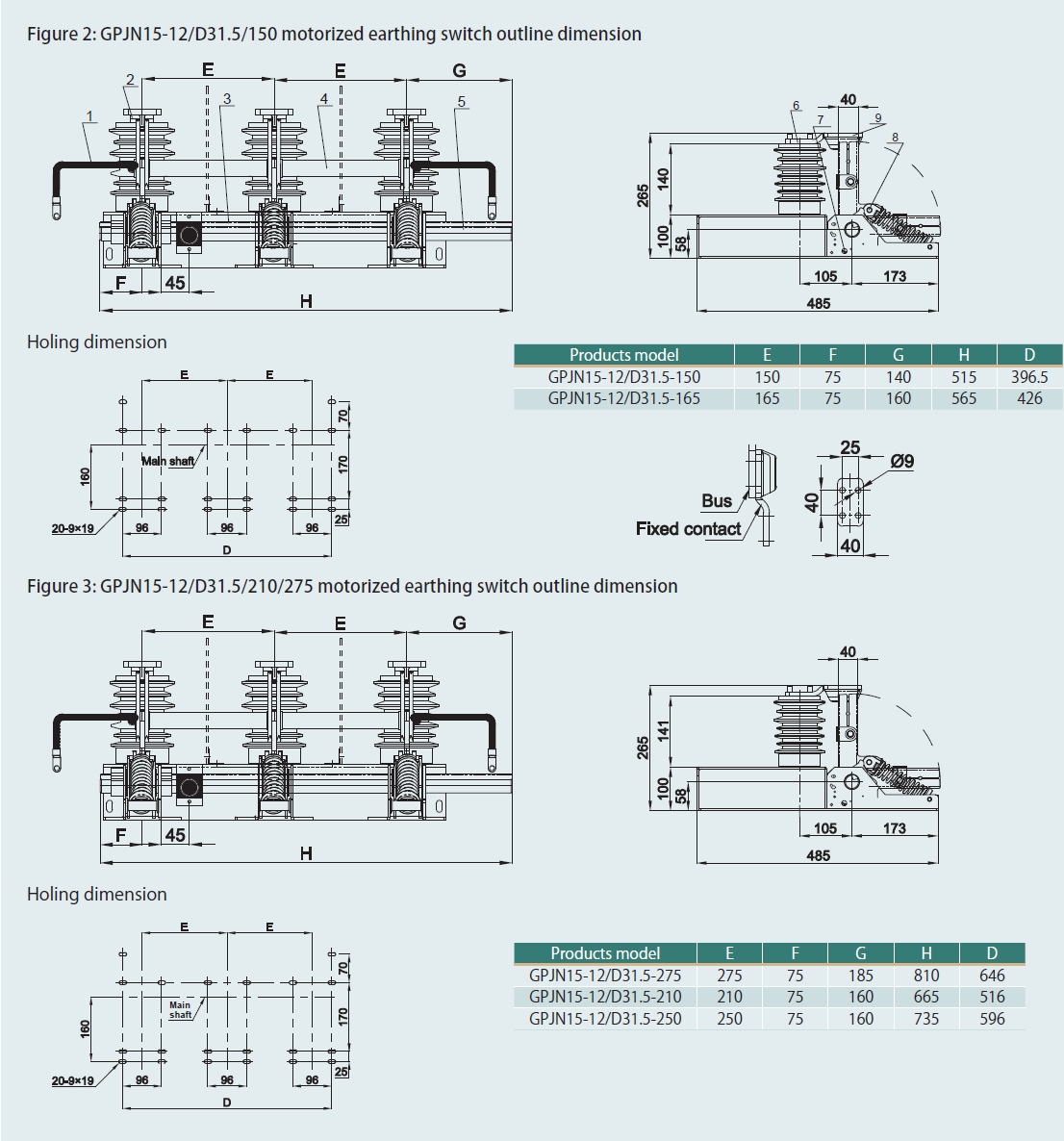

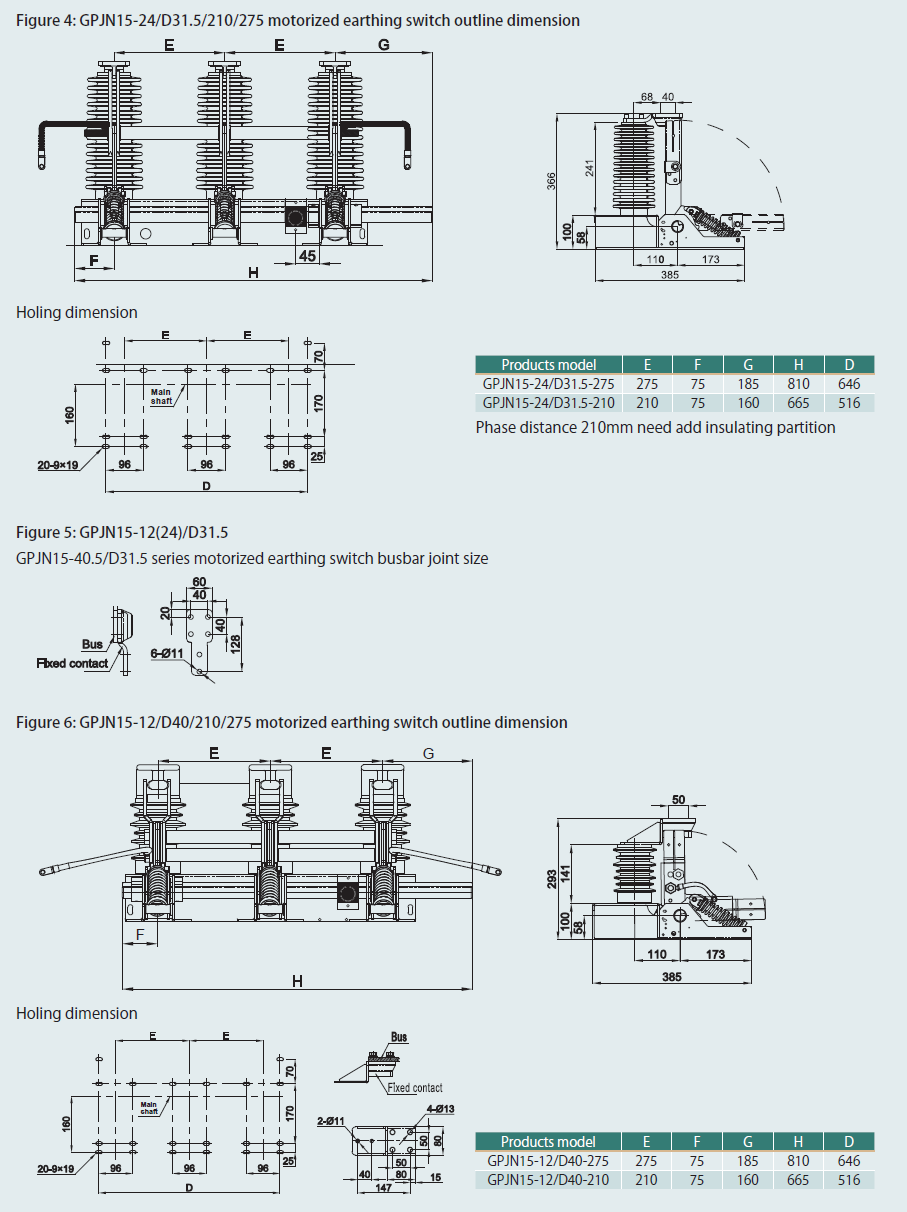

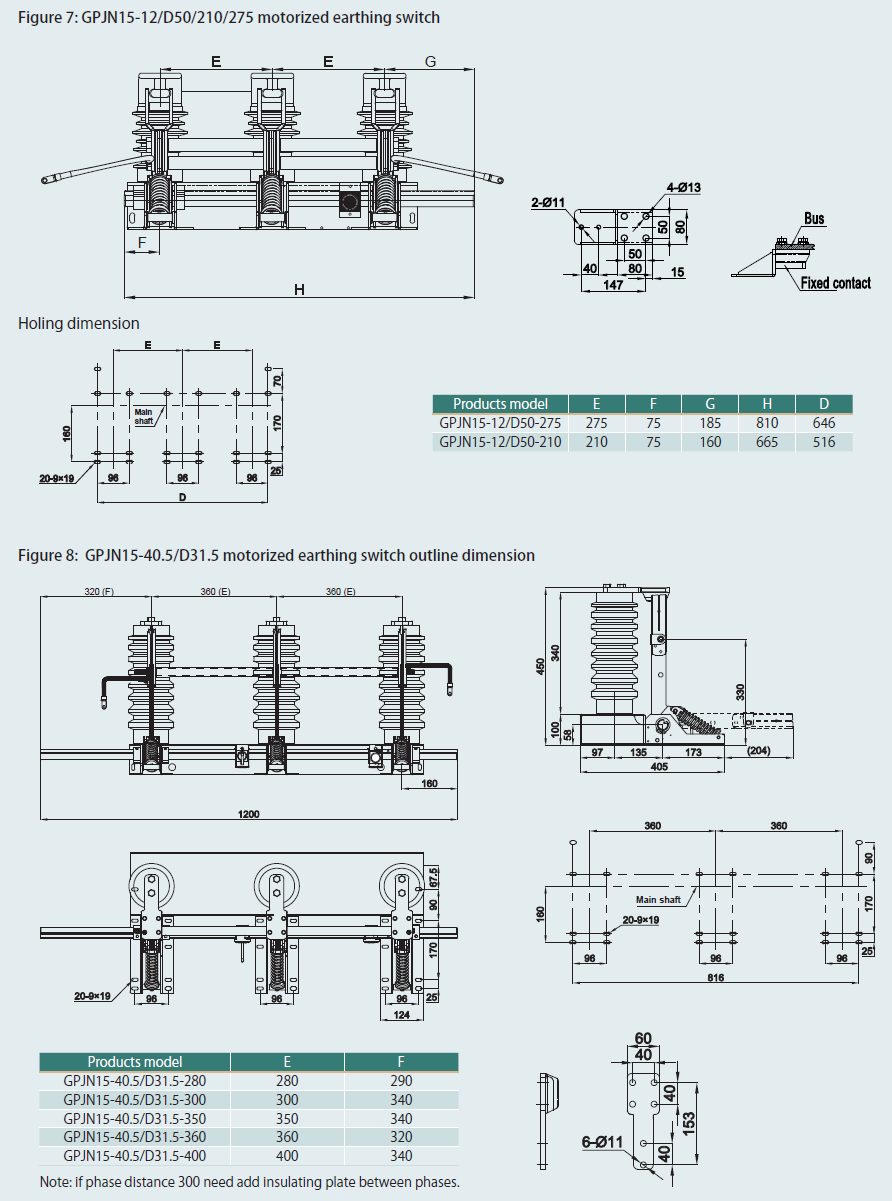

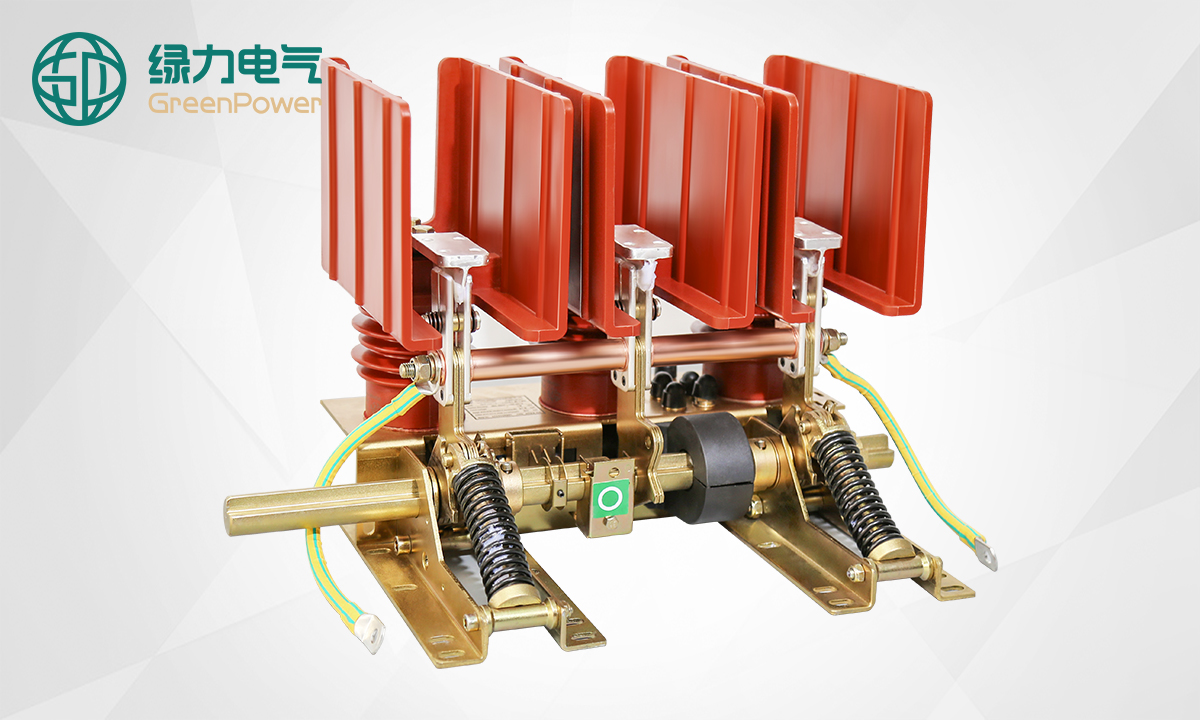

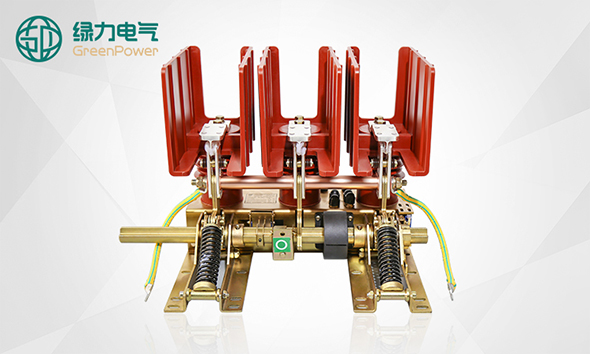

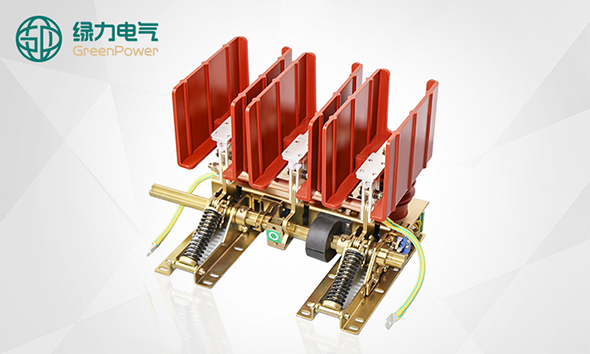

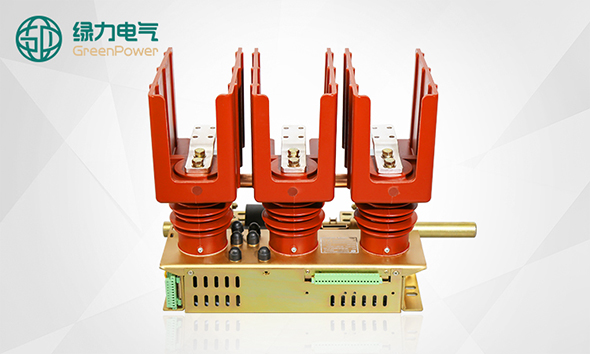

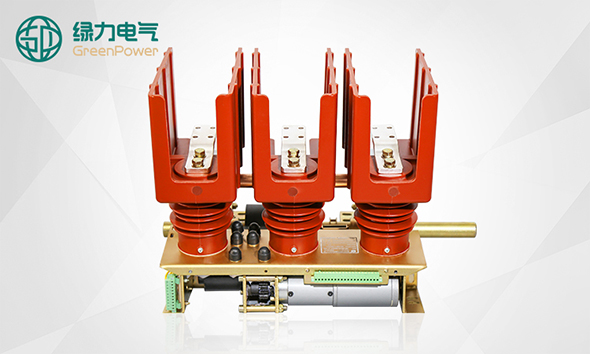

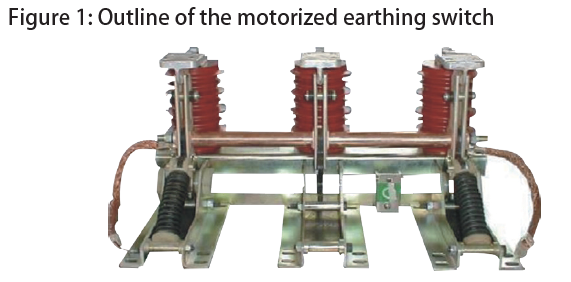

The earthing switch mainly formed by the holder, ground knife assembly, Fixed contact, sensors, shafts, crank arm, spring, conductive sleeve, flexible connection, curved rear bracket by a thin steel plate welded into parts, the rest are assembled components. Its shape, see the following picture:

2. Earthing switch works principles (in Figure 2, for example)

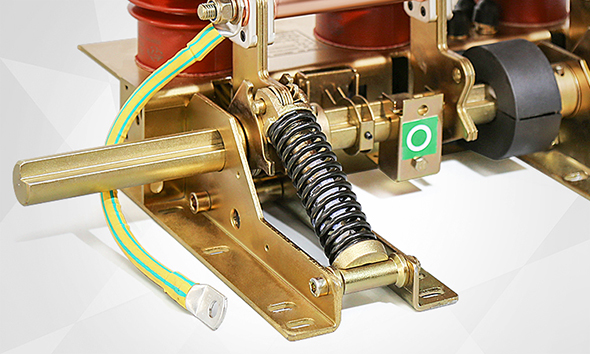

When the manually operated earthing switch closed, the torque force to the shaft 5 to overcome the drag torque, driving crank arm 7 rotates in the closing direction, and the operation rod on the earthing knife 9 through pressure spring 8 dead point, spring release energy, the grounding switch rapidly closing, on the closing position, earthing knife of earthing knife components 9 through the butterfly spring and knife mouth of fixed contact 6 to earthing firmly and securely.

When manual operation opening, the torque force to the shaft 5 and the spring force to overcome the resistance torque, drive crank arm 7 along the opening direction of rotation, and earthing knife 8 and pressure spring 9 through the dead point, spring energy storage finished in order to prepare for the next closing times.

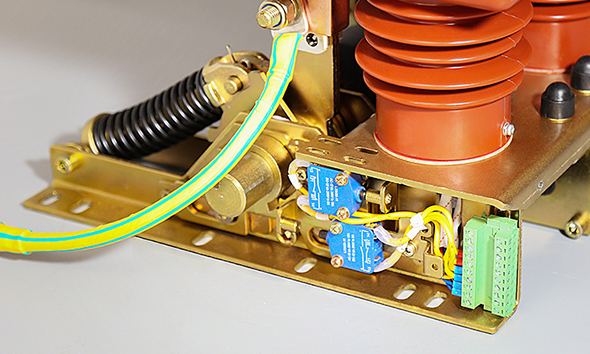

When electric operation, earthing switch inside has bevel gear, reducer, motor, control board which combined to drive device, this device output torque forward and reverse directions, so that the earthing switch opening or closing.

Whether earthing switch is manually or electrically operated, it is regardless of the speed of closing and opening the earthing switch.