10~40.5kV Neutral Earthing Resistors Device

General

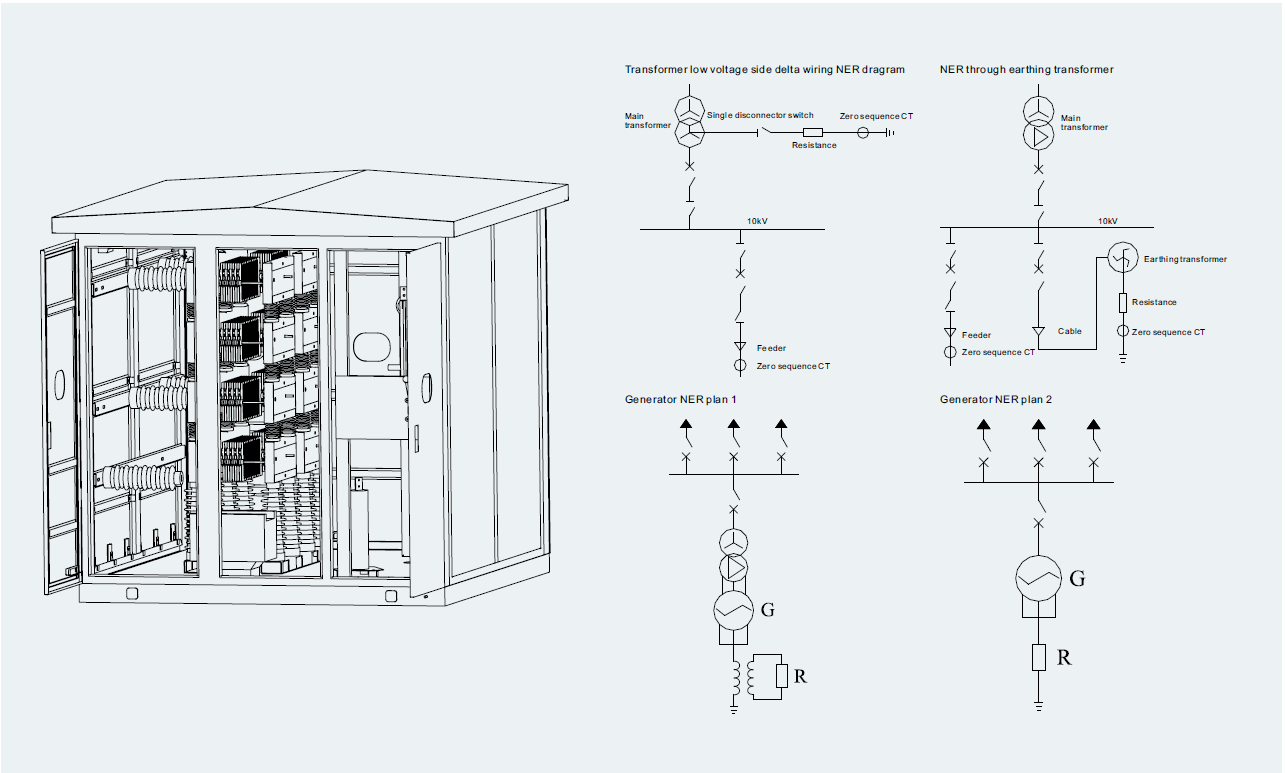

GP-NER Series neutral earthing resistors are applied to city electric power customer such as large-scale industrial enterprise, airport, harbor, metro ect., large generators and service power supply system in power plant, others.

The components of GP-NER series neutral earthing resistors are made of special stainless steel electric-heat metal imported from US. They are with outstanding characters such as high temperature-resistant capability, excellent anti-oxidation performance, strong tensile characteristics, high resistivity and stable resistance value, what’s more, it can sustain electric and thermodynamic performance even under 1000℃, which enables safe and reliable operation.

According to different connection mode or various customer requests, are can provide epoxy resin to cast dry type transformer, zero sequence current transformers, single-phase disconnecting switches. Heater and thermo/humidity controllers etc.

Applied standards

DL/T780-2001 Neutral earthing resistors in electrical power distribution system

GB6450 Dry type electrical transformer

IEE32-1972 Technology terms and test of neutral earthing resistors

GB/T11022-1999 Electrical equipment delivery testing criterion of electric device installation other national criterion and electric power industry standards.

Product features

GP-NER series neutral earthing resistor components are made of stainless steel alloy that is composed of special composition and used specially for neutral earthing resistor. The primary characteristics are as follow:

High temperature-resistant: The melting point is at 1375~1500℃, and its max working temperature is 1000℃.

Strong capacity of tensile strength: the intensity is at 700 Mpa, and mechanical intensity keeps constant at the high temperature of 900~1000℃.

High resistivity: The resistivity is 1.25 Ω .m, which is propitious to reduce the size of resistor component.

Stable resistance value: The resistance temperature coefficient is 1.05x102 Ω /℃, resistance value increase at high temperature is little, that is good for the sensitivity of protection.

High anti-oxidation performance: Resistance also has a high anti-oxidation performance even at the temperature of 1000℃, which is deeply suitable for seriously contaminative environment.

High tenacity: Resister elements can keep high tenacity when the temperature changes acutely.

Various type: According resistor’s current, there are several kinds of elements such as strap, grid, Spiral Wound, Ribbed Wound, smooth winding types etc.

Resistor modularized: each type resistor is made of standard components, by series connection or parallel connection to achieve kinds of parameters, elements can be replaced easily.

Optimal heat-dissipation design: the cabinet structure possess the optimal cooling air current passageway. The effect of heat dissipation is very good and there are no local overheat spots and burn spots.

Long operation life: The guarantee life is 30 years. Some resistors have operated for more than 50 years.

Specification

Voltage: 0.4kV~110kV

Rated current: optional

Nominal resistance: optional

Current duration: 10s, 30s, 60s, 10mins, continuous

Incoming and outgoing line: top in bottom out, bottom in and out, side in and out, side in bottom out, etc

Installation site: indoor / outdoor

Allowable temperature rise: 760 ℃ for 10s, 30s, 60s and 610℃ for 10min and 385℃ for continuous

Zero sequence current transformer: Optional