24kV SF6 Gas Insulated Ring Main Unit

GPR1 series gas insulated ring main unit (hereinafter referred to as GPR1 ring main unit) uses SF6 gas as the insulation medium. SF6 gas has strong electronegativity, high dielectric strength, and insulation strength 2~3 times that of air. It is non-toxic, odorless, non flammable, and non explosive. It has excellent arc extinguishing and insulation performance, allowing the load switch/circuit breaker to quickly extinguish the arc after breaking the current. Its internal design has a compact structure and small volume, saving space and resources. The gas tank adopts a stainless steel welded fully sealed structure. The operating mechanism adopts a spring type, with a simple structure and flexible operation, and the operating speed is not affected by the size of manpower. The mechanism has complete mechanical locking and reliable interlocking. Adopting modular design, it can be flexibly combined into various distribution schemes to meet the diverse needs of different occasions and users.

GPR1 ring main unit is suitable for the 3.6~12kV three-phase AC 50/60Hz power system as a means of receiving and distributing electrical energy. It is widely used in oil-free, safe and reliable small distribution stations, switching stations, urban residential communities, airports, railways, tunnels, and high-rise buildings. Especially suitable for various places with harsh environmental conditions and polluted environments such as industrial and mining enterprises, mountainous areas, plateaus, and coastal areas.

Altitude: Less than 3000m;

Ambient temperature: Maximum +40℃, Minimum -25℃;

Earthquake intensity: Not exceeding 8 degree;

Use in environments that can withstand dust, moisture, and short-term immersion in water.

Note: When the actual use environment conditions are inconsistent with the above conditions, please consult with our company.

IEC 60265-1:1998 High Voltage Load Switches Part 1: Load Switches with Rated Voltages Above 1kV and Below 52kV

IEC 60298:1990 AC Metal Enclosed Switchgear and Controlgear Above 1kV and Below 52kV

IEC 60694:2002 Common Technical Requirements for High Voltage Switchgear and Controlgear Standards

IEC 62271-100:2012 High Voltage AC Circuit Breaker

IEC 62271-102:2012 High Voltage AC Isolation Switch and Earthing Switch

GB/T 3906-2006 3.6kV~40.5kV AC Metal Enclosed Switchgear and Controlgear

GB/T 3804-2017 3.6kV~40.5kV High Voltage AC Load Switch

GB/T 1984-2014 High Voltage AC Circuit Breaker

GB/T 1985-2014 High Voltage AC Isolation Switch and Earthing Switch

GB/T 11022-2011 Common Technical Requirements for High Voltage Switchgear and Controlgear Standards

GB/T 16926-2009 AC High Voltage Load Switch - Fuse Combination Electrical Appliances

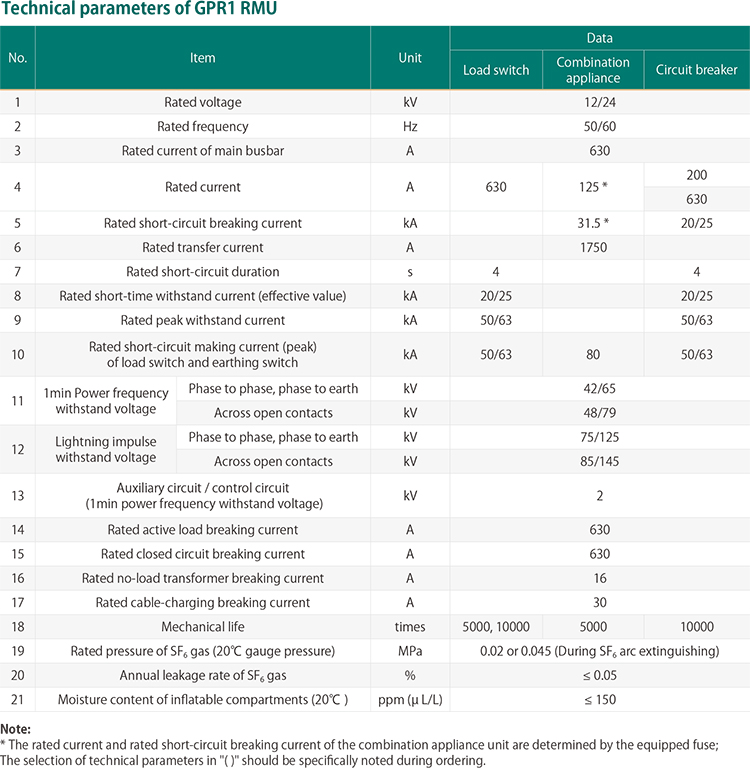

The main components and springs of the mechanism are made of imported materials to ensure reliable operation. The operating life of the load switch reaches 5000 times, and the operating life of the circuit breaker reaches 10000 times.

The processing technology of injection molded parts and sealing parts is advanced and strictly tested, with a service life of ≥ 30 years.

Adopting advanced equipment such as ABB automatic welding robots and Leybold helium leak detection system, ensuring an annual relative leakage rate of SF6 gas of ≤ 0.05%.

By using vacuum dehumidification technology, the micro water content of SF6 gas can be controlled to ≤ 150 ppm.

The inflation pressure is low, and under zero gauge pressure conditions, the switchgear can operate normally and achieve rated current opening and closing.

The harmonious unity of fixed and flexible expansion allows for the configuration of multiple modules in the same SF6 insulated gas chamber, or the use of extended busbars to connect the switchgear, achieving a semi modular structure.

GPR1 ring main unit is mainly composed of two parts: the cabinet body and the sealed stainless steel gas tank. The cabinet is divided into operating mechanism box, cable box, secondary instrument box and other parts. Each functional unit and the cable box are separated into independent compartments by metal plates, which do not interfere with each other and can effectively prevent the impact of faults in a single compartment. to other compartments to maximize the scope of fault control. The busbar, load switch, circuit breaker, connecting conductor, etc. are all installed in a sealed stainless steel gas tank. SF6 gas is used as the insulation and arc extinguishing medium. It is small in size and simple in structure.

The protection level of the GPR1 ring main unit enclosed is IP3X (IP4X is optional), the protection level of the stainless steel gas tank is IP67, and the protection level of the fuse barrel is IP67.

The enclosed of GPR1 ring main unit and the partitions of each functional unit compartment are made of high-quality cold-rolled steel plates that are processed and bent by CNC machine tools and other equipment, and are assembled with high-strength rivets, nuts and bolts. They have high mechanical strength and excellent corrosion resistance. Compared with similar equipment, it has the advantages of high precision, light weight, high mechanical strength, and beautiful appearance. At the same time, due to the modular design, the versatility and interchangeability of parts are improved, which can effectively shorten the processing cycle and reduce Production area. The cabinet surface spraying process adopts the world's most advanced electrostatic powder automatic spraying production technology, which has the advantages of beautiful topcoat, strong adhesion, corrosion resistance, high hardness, anti-aging, and good gloss and color retention.